LED Neon Flex Light Manufacturer

Mikoo, the most trusted LED neon flex manufacturer, has over 10 years of lighting manufacturing experience, we use SMT from SAMSUNG, a reflow soldering machine, to produce high-quality led strips, then use silicone material produce to led neon flex lights.

We use durable surface-mounted LED chips to ensure consistent brightness. Our brand LED chips can produce approximately more than 90 lumens. 100% copper PCB, and high-quality silicone materials have made our LED flex durable and efficient.

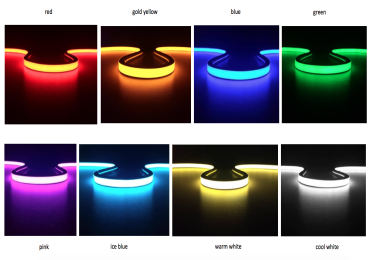

Mikoo produces LED neon flex lights in different colors, such as white, cold white, warm white, blue, red, green, yellow, purple, pink, ice blue, lemon yellow, RGB, RGBW color. Our versatile neon flex made of high-quality raw materials has high ingress ratings. You can use our custom LED neon flex in different applications.

Whether you need customized or pre-designed led neon flex, Mikoo will ensure the quality and meet your needs. All of our LED flex comes with 2 years warranty. So, you can use our durable LED neon flex without being worried. We can deliver high-quality LED neon flex within 8 to 15 days based on your quantity.

Silicone led neon flex available size are 5x12mm, 6X12mm, 8x16mm, 10x20mm.

Supply 12v (2.5cm cut unit and 1led cut unit) single color, RGBW/RGB 12v(5cm cut unit) and 24v(10cm cut unit).

LED Neon Flex Fake Silicone, also called newly PVC, available size for 6x12mm, 8x16mm.

Provide low voltage 12v(2.5cm cut unit and 1led cut unit) and 24v(5cm cut unit and 1led cut unit)

PVC led neon flex available size are 7x15mm, 8x16mm, 10x20mm, 10x25mm, 12mm, 14mm, 16mm.

Provide low voltage 12v( 2.5cm/5cm/10cm/25cm/50cm cut unit) and 110v/220v.

Your Reliable LED Neon Flex Light Manufacturer in China

Mikoo LED neon flex is used in different residential and commercial lighting projects. You can use our neon flex for home decoration, facade lighting, contour lighting, and cove lighting. You can also use our led neon flex for backlighting, swimming pool lighting, and other lighting projects.

Mikoo’s silicone material ensures that you can use neon flex for a longer period of time. You can bend our neon flex in any direction for high flexibility. You can also design your lighting project for its flexible printed circuit board.

As one of the leading manufacturers and suppliers of LED neon flex, Mikoo has CE, RoHS, ETL certifications. Our skilled worker team will inspect raw materials, production processes to provide durable and good quality LED neon flex.

We offer LED neon flex samples to check the quality before you place an order. We will provide a detailed catalog and videos to check the quality of our LED neon flex.

Besides LED neon flex, Mikoo produces high-quality LED strip lights, neon signs, LED rope lights, and Christmas LED lights. Whether you are a neon flex distributor or retailer, Mikoo is always your reliable business partner.

Send us your details of lighting projects to get a free quote.

- Manufacturing

- Technical Structure

LED Neon Flex Light Manufacturer

Technical Structure

LED Neon Flex – The Complete FAQ Guide

Do you wonder why big cities seem colorful at night?

Yes, those are LED Neon Flex which makes the night alive and attractive. With the wide use of LEDs today, the traditional neon glass and other fluorescent lamps are now replaced by the more efficient and cost-effective LED neon flex lights.

This ultimate guide is prepared to help you select your next LED neon flex to your designs.

What Is LED Neon Flex?

The “flex” in LED neon flex stands for “flexible”. It is the world’s most uniform linear lighting. Manufacturers use SMD LED chips to make them high quality and ensure high brightness.

The LEDs are mounted in tiny circuit boards, carefully wired, and jacketed into a run of silicone, fake silicone, or PVC tube. This silicone or fake silicone tubing is flexible enough to be designed into different shapes and sizes.

This 21st century’s neon flexes are eco-friendly and consume less energy.

What Are the Advantages of Led Neon Flex?

Let’s try to find the advantages of LED neon flex.

Safe to Use

The average input voltage of LED neon flex ranges from 12V, 24V, 120V to 220V.

Durability

The manufacturing process, raw materials, brand LED chips, installation process, and user’s maintenance affect the lifespan of LED neon flex. The average lifespan of LED neon flex is about 50,000 hours. So, you don’t need to purchase neon lights again and again.

Easy Installation

You can give any shape of LED neon flex by cutting and bending. These lights come with all pre-set accessories. You just need to plug and turn the lights.

Can I Cut the Length I Need?

Every LED Neon flex comes with cut marks where you can cut them. The distance between the two cut marks depends on the LED neon flex lights models. The distance between the two cut marks is no longer.

You will get cutting marks or scissor marks on the LED neon flex lights. Cut only on these marks with sharp scissors or knives.

What Are the Differences Between RGB LED Neon Flex Light and RGBW LED Neon Flex Light Difference?

An RGB LED neon rope light is a type of light with a combination of red, green, and blue led chips. And, RGBW is a type of rope light with a combination of red, green, blue, and white led chips.

Though RGBW neon rope lights are expensive, RGBW LED neon rope lights are brighter and purer than RGB LED neon rope lights. The additional led chips have increased the price of the RGBW light. You will get different colors and dynamic effects through these two types of neon rope lights.

So, which one should you buy? The better option between these two types of neon rope lights depends on you and your project’s requirements.

If you don’t need many color options for your projects, you can use RGB led neon rope lights. RGB LED neon rope lights are also cost-effective.

If your projects require numerous color combinations, then RGBW LED neon rope lights are perfect for you. You can create any dynamic effects with RGBW LED neon rope lights.

What Size of LED Neon Rope Light?

LED neon rope lights have different sizes. You can choose the following pre-set sizes or you can order a customized size for your projects.

- 5x12mm

- 6 X 12mm

- 7X15mm

- 8 X 16mm

- 10 X 20mm

- 15 X 25mm

- 16 X 16mm

- 12mm, 14mm, 16mm

What Material of Led Neon Rope Light?

We use different kinds of materials such as silicone, fake silicone, and PVC. LED neon flexes made of high-quality silicone materials last for a longer period of time.

What Are the Applications of LED Neon Flex?

You can use LED neon flex for different kinds of lighting projects. Let’s see some common applications of LED neon flex.

Facade Lighting

As LED neon flexes are very flexible, they adapt to the building facade. You can shape it to any streamlined lighting design to get the desired vivid and artistic lighting effect. You can use these lights for large area installation. With neon flex, you can generate advanced chasing scenes and create visual effects.

Cove Lighting

LED neon flex lights are suitable for cove lighting. Create an artistic look at your ceiling and walls of the room.

Contour Lighting

To showcase the essence of contour lighting, you can use LED neon flex. You can make any drawing more vivid. Various lighting color modes of LED neon flex offer dynamic pigment in the lighting projects.

Backlight

You can highlight the subjects of lighting areas by using LED neon flex. Project planners and wholesalers use LED neon flexes because of their high-efficiency and low power consumption.

Swimming Pool

Do you want to miss the animated lighting atmosphere at your pool parties? You can decorate your pool with LED neon flex. Just attach the LED neon flex along the side of the swimming pools. You can also hang them in the trees.

How Do You Use LED Neon Flex?

LED neon flex is used for different kinds of lighting purposes. Let’s see some specific uses of LED neon flex.

- Canopies

- Cupolas

- Staircases

- Balconies

- Proches

- Cornices

- Gables

- Porticos

- Moldings

- Shopping Mall

- Retail Establishment

- Restaurant

- Hotel

- Bar

- Country Club

- Apartment Complex

There are lots of other uses such as advertising signs, a lighting fixture for indoor or outdoor use, commercial applications, etc.

What Is the Difference Between LED and Neon Glass Lights?

The popularity of LED neon flex is increasing day by day. Project planners are using LED neon flex and resurfacing their old neon glass lights with LED neon lights.

But why?

Let’s compare these two types of Lights so that you can choose the right for your projects.

Energy Efficiency

LED neon flex consumes about 10-15 times less energy compared to neon glass signs. Let’s see how much you can save by installing LED neon flex instead of neon glass signs.

| Type of Light/ Headings | # of feet used | Power Consumption per foot | Total Power Consumptions per day | Total power consumption per year( 12h/d) | Cost per kilowatts | Total annual energy cost |

| Neon Glass Signs | 50 | 20 watts | 1000 watts | 4,380,000 watts or 4380 kilowatts | $.10 | $438 |

| LED neon signs | 50 | 2 watts | 100 watts | 438,000 watts or 438 kilowatts | $.10 | $43.8 |

Saving = ( $438 – $43.8) = $394.2

So, you can save ( 394.2 * 100/438)= 90 percent of energy.

Durability

LED neon flexes are more durable than traditional neon glass lights. The external soft stroke can break the glass lights.

On the flip side, LED neon flex is made of Silicone. LED neon flexes of Mikoo are waterproof, dustproof, and corrosion-proof. So, you can use them for a longer period of time.

Affordability

The upfront cost of traditional glass neon is higher compared to LED neon flex. You also need to pay more for repair and maintenance.

On the other hand, the purchasing cost of LED neon flex is very low. You can also easily replace the light yourself. Just assemble the lights and plug them into the power source.

Safety

As LED neon flexes consume less energy, they produce less heat. You and your children can touch them with bare hands. So, you can set them in almost all places at your home.

Neon glass lights are made of glass and consume more energy. So, they become very hot after turning the lights on. Your hands will burn if you touch them with bare hands. Besides, they may cause damage in case of dropping from the installation.

Installation and Maintenance

You don’t need any special installation team members to install LED neon flex. Just cut them according to your lighting requirements and set them on designs. You can also clean them easily.

The traditional glass neon lights are fragile and heavy. So, they require special technicians for installation and maintenance. The maintenance of these types of lights is also complex. You need some special tools to repair them.

Portability

As traditional neon glass lights are heavy and fragile, you can’t carry them from one place to another easily. You need to use special packaging systems to carry them from one place to another.

LED neon flexes are very lightweight and so they are very portable. Project planners of marriage lighting and stage lighting need to carry their lights from one place to another. Just fold LED neon flex or keep them in a bag. Then carry anywhere you want without being worried about breakage.

Lifespan

Manufacturers use neon gas and other gases to produce neon glass signs. So, the brightness starts to decrease after a few months. The average lifespan of neon glass signs is approximately 10,000 to 15,000 hours.

On the flip side, LED neon flex is made of high-end raw materials and brand LED chips. Some eminent manufacturers such as Mikoo use surface-mounted LED chips. So, they last more than 50,000 hours without flickering.

Is LED Neon Flex Waterproof?

Yes, this is often specified by the IP68 rating. The higher the rating, the more waterproof your flex will be. If you want to install LED neon flex in outdoor lighting solutions, pls choose our waterproof supply power and controller, make the connector part waterproof.

What Factors Should You Consider at the Time Choosing LED Neon Flex?

There are different types of LED neon flex available in the market. The price varies based on size, quality, and other factors. Low-quality product damage in a few months. You need to repurchase if you purchase low-quality products.

There are 4 factors to consider before beginning your purchase:

Color and Effects

You need to determine what kind of color you need, or possibly a combination of colors. Would it be static or changing colors, or chasing light patterns? The visual effects you can think of are just limited by your imagination.

You need control electronics which may require you to purchase additional accessories, for the custom application.

Cutting Unit Length

When calculating the length of flex, you need, any run of length must be divisible by the “cutting unit length”. First of all, determine the total brightness required for your lighting projects. Then, check the brightness of your LED neon flex per meter.

Finally, calculate the required length of your LED neon flex. In this modern-day, the brightness of LED lights is calculated by lumen rather than watts.

Bending Radius or Bending Diameter

There are small circuit boards inside the silicone tube, hence, you can bend the flex only to a certain extent without breaking the LED circuit inside the flex. Check your manufacturer’s product specification.

The higher the flexibility of LED neon flex, the better for lighting designers to design lighting projects more perfectly.

Connection Types

To connect the flex into a power source, there are two types of connectors you may use:

- Prefabricated Injection Molding – Pre-installed from factory and ready to mount during assembly

- Snap Connector – is a DIY connector the user can do onsite. You may need good quality PVC cutter to make a firm cut on the “cut” marking of the flex

How to Wire LED Neon Flex Light?

Project planners and lighting designers purchase LED neon flex in a longer length. So, they need to cut them to design their projects. Before wiring LED neon lights, collect the necessary equipment.

- Knives or Scissors

- Heat Gun

- Silicone Sealant

- Flat-nosed Pliers

- All other accessories come with LED neon flex.

To wire the LED neon flex light, follow the following step by step guide.

Step 01: Cutting LED Neon Flex

All LED neon flexes come with cutting marks of dashed or scissors signs. Use knives or heavy-duty shears to cut through LED neon flex. Check the sharpness of knives and scissors to make a straight cut.

Step 02: Connecting the Power Pin

Connect two LED neon flex with splice connector. Tighten them carefully so that the parts of LED neon flex don’t flicker.

Step 03: Connecting Power Cord, Jumpers, and Connectors

Warm the molded female power connector and make them malleable with a heat gun. Attach the female pin openings with the male power pin of LED neon flex. If you want to install LED neon flex for outdoor lighting projects, apply the bead of silicone sealant ceaselessly around the LED neon flex’s perimeter.

Now, you have connected one end with a power cord. Using the above method described above, attract the jumpers or connectors to another end.

Safety Precautions: Before starting any electrical work, use the safest materials to avoid any personal injury and other accidents.

How to Choose a Reliable Manufacturer of LED Neon Flex in China?

Most of the Importer, project planners, and wholesalers around the world choose China products for their efficiency.

You will get the most durable products at affordable prices. There are many lighting industries in China. So, finding a reliable manufacturer of LED neon flex is troublesome but not impossible. You need to know the answer to the following questions about manufacturers.

- Do manufacturers have experience in the lighting industry?

- What is the capacity to produce LED neon flex?

- Do they follow the international standards of the lighting industry?

- What are the terms and conditions of after-sale services?

- What is the average delivery time of products in your countries?

- Do they follow the internal quality control systems with experts?

- Do your manufacturers follow convenient payment systems?

If the answers to the above questions meet your requirements, contact them directly. Before purchasing, know all the terms and conditions of the manufacturers. You also can send us inquiries, we are happy to serve you in 7X24hours.

What Are the Necessary Accessories Required for LED Neon Flex?

For smooth lighting, you need to choose high-quality accessories of LED neon flex. Most LED neon flex manufacturers provide necessary accessories with neon flex. Whether you get from the manufacturers or purchase from other sources, confirm that you have the following accessories.

- Mounting Clip

- Aluminum files.

- Aluminum Channels

- End Cap

- Splices

- Power cable

- Connector to neon

- Power Cord Kits

- Jumper Cables

- Controllers and receivers ( In case of RGB Neon Flex)

You may not require all accessories. Choose the accessories according to your project’s requirements. Be confirmed that your neon flexes will last for a longer period of time.

How Flexible Is LED Neon Flex?

You can bend the standard LED neon flex in any shape you want. 90°, 180° , 360°. Bend them in any direction. So, you can design any complex lighting work with LED neon flex.

But, you should be careful at the time of bending the RGB neon flex. RGB neon flexes come with internal copper wire. The copper wire may damage if you bend them equal or greater than 90°.

Please check product specification, manufacturers do specify the minimum bending diameter of the flex.

How to Troubleshoot LED Neon Flex?

You don’t need to replace the old LED neon flex in case of flickering or stop working. You can easily troubleshoot and solve them.

When Entire Fixture Doesn’t Work

- If the entire fixture doesn’t work, check whether the power supply is plugged in or not.

- If the power supply is okay, check the dimmer or controller connection, the polarity of all wire connections.

- Also check the output voltage of the power supply, connector pin.

In the case of Dim or Dull at One End

- Adjust the dimming level

- Attack a lead wire to both ends of LED neon flex or Shorten them to prevent voltage drop.

In case of high brightness

Check the voltage of the power supply. Keep the voltage of the power supply lower than that of LED neon flex lights.

Can You Control LED Neon Flex’s Color?

Yes, depending on the type of flex lights you use. For custom design, you need special accessories such as LED Controller for this functionality. To get various colors, you can purchase either many LED neon flexes or single color-changing RGB LED neon lights.

Here are some popular colors of LED neon flex.

- White

- Warm White

- Blue

- Iceblue

- Amber/Yellow

- Lemon Yellow

- Orange

- Green

- Red

- Pink

- Purple

- RGB LED Neon Flex

- RGBW LED Neon Flex

What Power Supply Does LED Neon Light Require?

Two main factors determine the voltage supply needed to power LED neon lights:

- Run-length

- Brightness

The longer the length required, the higher the voltage supply is needed. More brightness also requires a higher voltage supply.

12V to 24V supply is enough for small areas, however, you may need a 120V or 240V voltage supply for commercial applications.

Final Words

You can add color, flair, and pizzazz to your home or commercial building. LED neon flexes enhance the stunning visual effects of corporate displays, entertainment venues, and architectures. The wholesalers can make a good profit due to the higher demand for LED neon flex.

Mikoo has established a research and development department with skilled technicians. We are using high-quality raw materials to produce LED neon flex. You will get the most durable LED neon flex at affordable prices with good quality.

Send us an inquiry to get a free quote and the hot sales product item catalog.